HOT AIR OVEN

Hot Air Oven are designed to generate heat with blower assisted air re-circulation inside the chamber at temperature from ambient+10°C to 150°C, 200°C or 250°C. In general, they are also called forced air circulating oven and widely used to dry glassware, sterilize N95 mask, general instruments and packaging items. They also used in life science, microbiology laboratory, MLSS analysis and many research based applications. There are various industries, where hot air circulating ovens are used such as, chemical and pharmaceutical industries, food and beverage industries, textile, electronic components and steel manufacturing industries etc.

The core job of a hot air oven is to eliminate moisture from the material; therefore, it is used in related applications such as curing, drying, baking, annealing, Measurement of mixed liquor suspended solids (MLSS) and even storage of certain products at constant temperature in laboratory and hospitals etc. Being a manufacturing company, we have developed our range of hot air ovens for microbiology, medical and general laboratory uses and light industrial applications. Meeting all performance standards and equipping with enhanced safety features including DIN12880, our laboratory hot air oven are considered most reliable forced air drying machines throughout India and worldwide.

We make hot air ovens in various temperature ranges, material of construction and chamber dimensions. Maximum operating temperature range of these ovens are 150°C, 200°C and 250°C which is controlled through microprocessor based PID temperature controller. It displays both set value (SV) and process value (PV). With the help of RTD PT100 temperature sensor, it measures the temperature precisely. Forced air circulation is obtained using branded motor driven blower system. For heating, we use sheathed air heaters. Each unit is fitted with over temperature protection device (safety thermostat), which keeps your oven and samples safe in case of controller failure.

A hot air oven must have attractive design, rugged construction and easy to clean surface; therefore, inner chamber of our ovens is made of thick gauge of stainless steel sheet (SS 304 / SS 316). Corners are such designed that cleaning becomes an easy job for operator. Shelves are made of stainless steel wire mesh cable; these are removable in order to adjust the height level. Depending upon size of internal chamber quantity of shelves may vary from 2 to 5 or more. External cabinet is made of either powder coated

GI sheet or stainless steel as required. For easy mobility of large hot air ovens, caster wheels with brake are fitted at the bottom.

We are hot air oven manufacturers, suppliers and exporters in India; having oven factory in Delhi, we have capability to develop any customized oven that fits your specific requirements. If you want to buy a hot air drying oven for laboratory or any other application, please choose from below mentioned standard models. If you have specific size and temperature requirement, we can also design the same oven at competitive price in India. There are several optional accessories are also available to fit in your hot air oven; such as, explosion proof heater, digital timer, PLC based HMI controller, RS485 computer interface, 21 CFR software, data logger and circular chart recorder and HEPA filter air inlet etc.

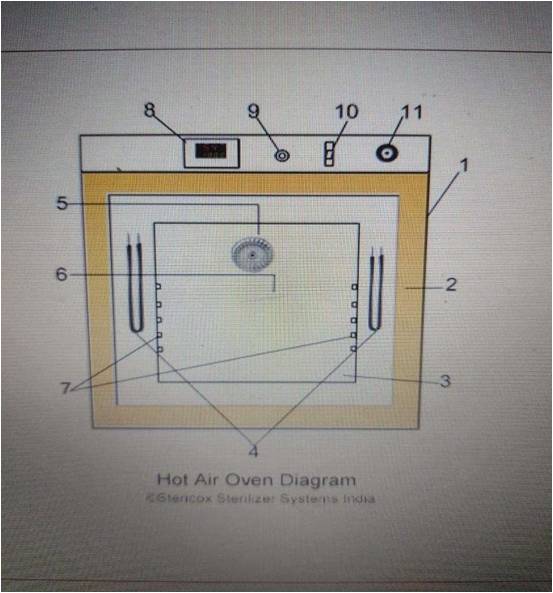

- External cabinet

- Glass wool insulation

- Inner chamber

- Tubular air heaters

- Motor driven blower

- Temperature sensor

- Tray slots

- PID temperature controller

- Load indicator

- Mains on/off switch

- Safety thermostat

- 40°C to 250°C temperature

- Uniform air circulation across chamber

- Digital temperature controller cum indicator

- Excellent uniformity at high temperature

- Stainless steel inner chamber

- Corrosion resistant exterior

- Fume ventilation points on both sides

- Steel wire mesh cable trays

- Over temperature protection

DETAILED DESCRIPTION

Temperature Range: The standard temperature range of a laboratory hot air oven is ambient+10°C to 150°C but we can also make up to 200°C and 250°C

·Temperature Controller: We always equip our hot air oven with imported and branded PID temperature controllers that feature auto-tuning and display both set value (SV) and process value (PV). It is also responsible for accuracy of temperature during the entire cycle. RTD PT100 sensor has sensitivity of

Heating Element: Sheathed Tubular air heaters are considered best for hot air ovens; these elements are ISI mark and from reputed brands in the market and offer fast heat up using minimum energy consumption

Air Circulation: In order to achieve better uniformity across the chamber, air circulation is mandatory; therefore, we use only branded motor and blower assembly for this purpose. It is fitted at rear side or top side of the chamber as per convenient

Construction: Rugged construction is prime requisite of any hot air oven; therefore, we use only stainless steel sheets of thick gauge that are nicely jointed through arc welding. External cabinet is usually made of powder coated GI sheet and for GMP models stainless sheets are used

Customization: We understand the requirement of customization; therefore, we offer number of optional features and accessories with our hot air oven such as toughened glass viewing window, perforated stainless steel shelves, 21CFR based controller, data logging and monitoring device, programmable soak timer, color touch screen controller etc.

TECHNICAL SPECIFICATIONS

| Temperature range | Ambient +10°C to 250°C |

| Temperature accuracy | ±05°C or better |

| Temperature sensor | RTD PT100 |

| Temperature controller | · PID temprature controller · Display of SV & PV |

| Construction | Double walled |

| Inner chamber | Stainless steel 304 |

| Exterior | Powder coated GI sheet |

| Insulation | Fiber glass Wool |

| Shelves | Chrome plated wire mesh cable trays (removable) |

| Door | Insulated solid door with spring latchp |

| Door gasket | Fiber glass door gasket |

| Air circulation | Motor driven blower assembly |

| Vent port | 2 fume vent ports (adjustable) |

| Safety | Over temperature thermostat |

| Power supply | 220 Volts / 50 Hz |

Optional

- Horizontal air flow

- Pass through (two side doors)

- Port hole for sensors & data monitoring

- Digital timer 99 hours 99 minutes

- Fan speed controller

- Programmable controller (multi-set points)

- Toughened glass window

- Stainless steel exterior (GMP model)

- Data logger with USB interface

- HMI & PLC automation

- EUROTHERM controller

- Caster wheels with lock

| Model No. | Size (Inch) | Size (mm) | Capacity (Liters) |

| EIPL-HAO-001 | 12″ X 12″ X 12″ | 300 x 300 x 300 | 20-50 L |

| EIPL-HAO-002 | 14″ X 14″ X 14″ | 350 x 350 x 350 | 50-100 L |

| EIPL-HAO-003 | 18″ X 18″ X 18″ | 450 x 450 x 450 | 101-150 L |

| EIPL-HAO-004 | 18″ X 18″ X 24″ | 450 x 450 x 600 | 151-200 L |

| EIPL-HAO-005 | 24″ X 24″ X 24″ | 600 x 600 x 600 | More than 200 L |